We use ASIA QUALITY FOCUS for our quality control. AQF is an independent 3rd party audit organisation

M&E Quality Control

Here at Merch and Effect, quality means everything. Every product manufactured undergoes tedious processes and inspections to ensure best output every time. As your products take its baby steps in production, we are there to guide them to the right path of being a high-class merchandise.

We take seriously the steps to assuring quality products. As we work with overseas manufacturers, it is best to be kept aware and very much updated with the processes that a product goes through. Through this, there will surely be lesser chances of production defects which may cause you a whole lot of time and money. As part of our service, Merch and Effect offers to you these different types of inspections to guarantee the best merchandise.

Why is a quality control inspection important?

Product inspections in China and Asia will check the status and quality of your goods, during all stages of production to ensure that all products meet your preferences. The quality control inspection will help all your requirements, specifications and criteria be implemented by the selected factory.

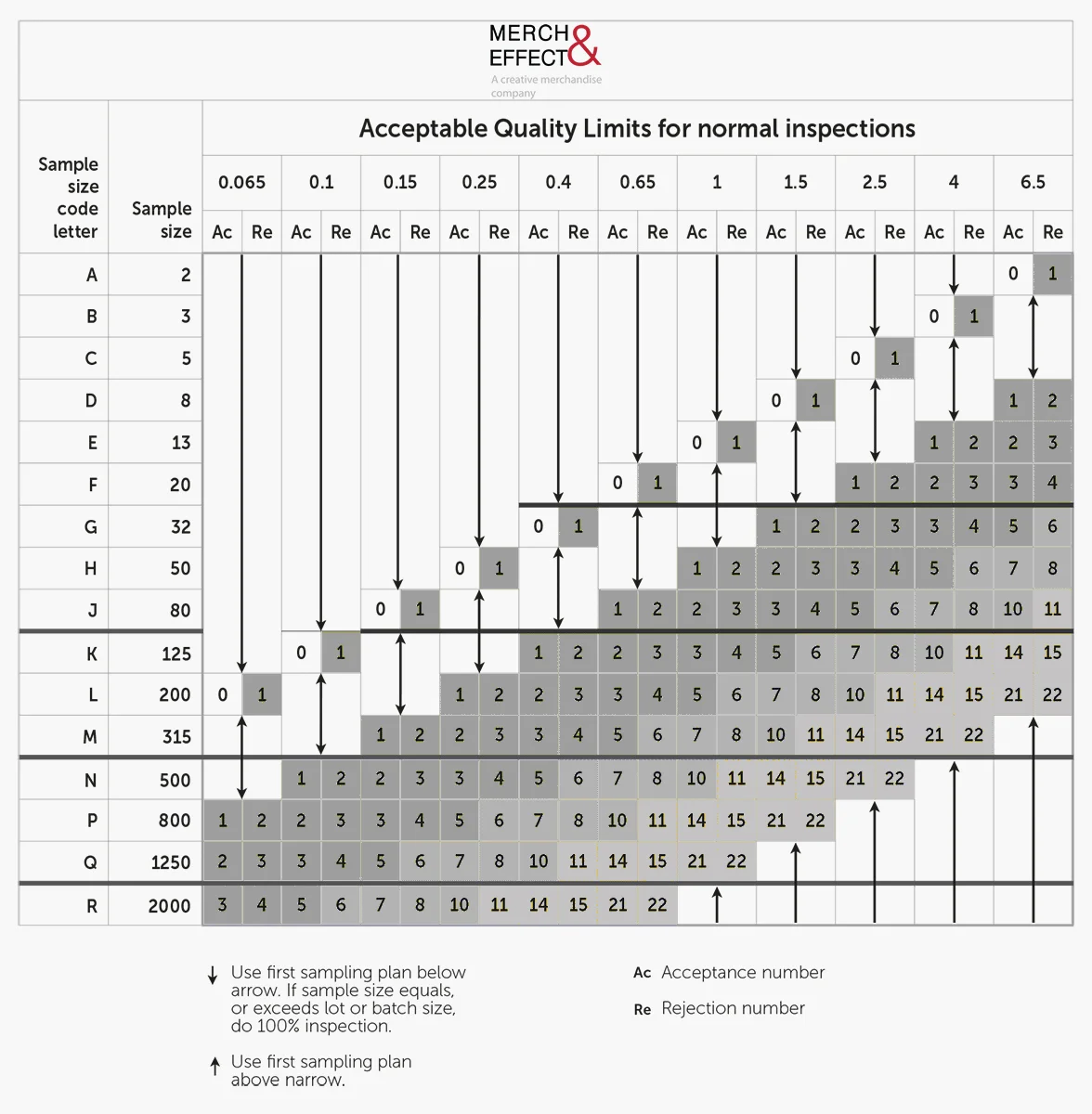

The product inspections are performed according to international quality control standards such as ANSI/ASQC Z1.4-2003, AQL standards, ISO 2859-1, but we also perform quality inspections that suit your company's needs and specifications.

Which product inspection should I choose?

We would recommend you to avail of our quality inspections for all the stages of production to ensure the best output with lesser chances of error. In order to save on costs, most clients purchasing low to medium volumes will only choose to inspect at 2 or 3 steps of the production, (our most availed inspections are the During Production and the Pre Shipment Inspection). We will be happy to assist your company to determine the best type of inspections that your product might need to get your investment's worth.

What should I do in the case of a failed inspection?

Note that ONLY YOU can accept or reject a shipment, so you get to decide how many defects are acceptable. It is the responsibility of the clients to study and assess the daily reports sent out by the factories and determine if their standards are met accordingly down to the last detail. You may also consult with us regarding the sampling size through our defect sorting service; feel free to ask.